Smart Industries

AI-Based IIoT Platform for

Optimizing Manufacturing

There is a way out of the existing energy crisis!

Our Benefits

IMPROVE YOUR MANUFACTURING KPI’S

Linked Things’ Industrial IoT platform is designed for the management to receive relevant, actionable insights from the plant and floor directly in their boardrooms to support decision making, increase the profitability, reduce the costs and enhance the quality.

Our Benefits

IMPROVE YOUR MANUFACTURING KPI’S

Linked Things’ Industrial IoT platform is designed for the management to receive relevant, actionable insights lives from the plant and floor directly in their boardrooms to increase the profitability, reduce the costs and enhance the quality.

Linked Things

OUR PRODUCTS

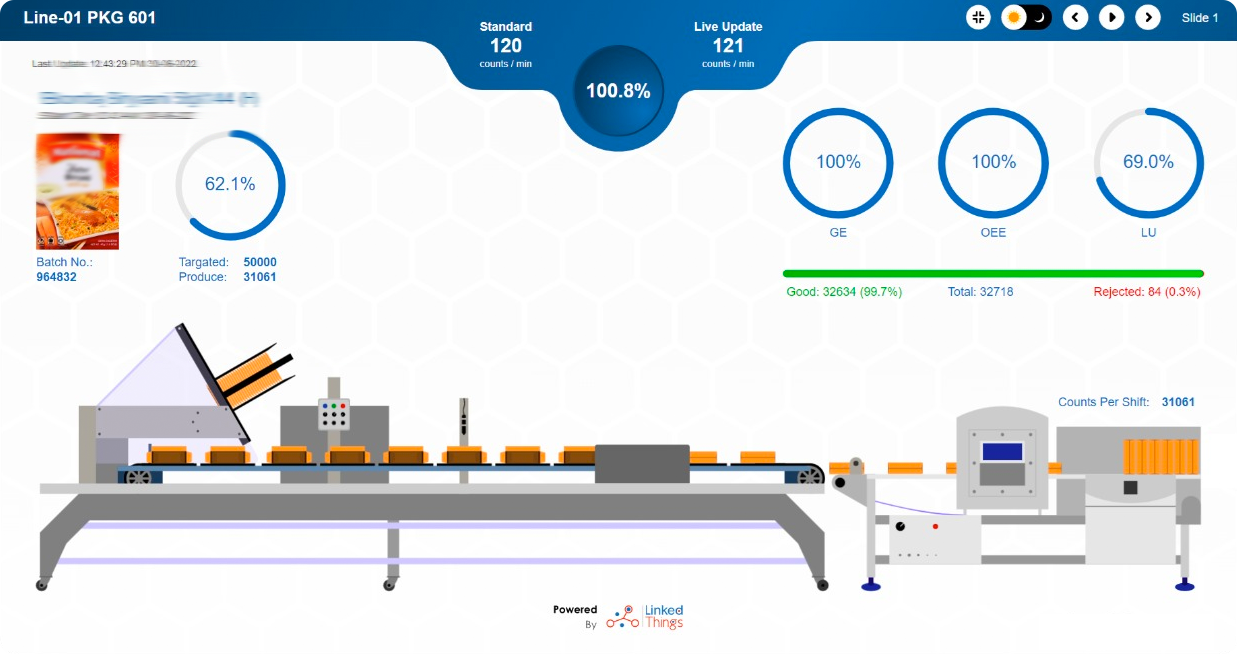

GE and OEE Calculations

GE and OEE are important KPIs in the manufacturing sector to determine the efficiency. We have deployed our sensors that monitor the production and down times and calculate GE and OEE in real time. The management has the line utilization and efficiency data whenever they need it to make a decision about increasing the production.

Tank Monitoring

We deploy sensors to monitor the inventory levels of water, edible oil, fuel oil, grains etc. The consumption pattern can be matched with the production and the data is useful for future planning. We also send the autogenerated messages to the suppliers to alert them to refill or the management to start planning procurement.

Predictive Maintenance

We monitor energy, hydraulic pressure, noise, temperatures and flows during production hours and predict maintenance requirements. This greatly reduces the down time, increases the lifetime of the equipment and helps in developing accurate production plan.

Quality Monitoring

Cold Chain is vital for food quality, a slight change in temperature over a period of time can compromise the quality and increases the losses for the food distribution companies. We have developed solutions that continuously monitor the storage at remote locations and alerts the staff not only about the food quality but about the freezers and cold rooms health status. This reduces the number of maintenance trips.

Proven Benefits

Food Processing Industry

We provide solution to monitor the temperature and humidity of silos and distribution vehicles so that the product quality is assured during transport and storage at various locations.

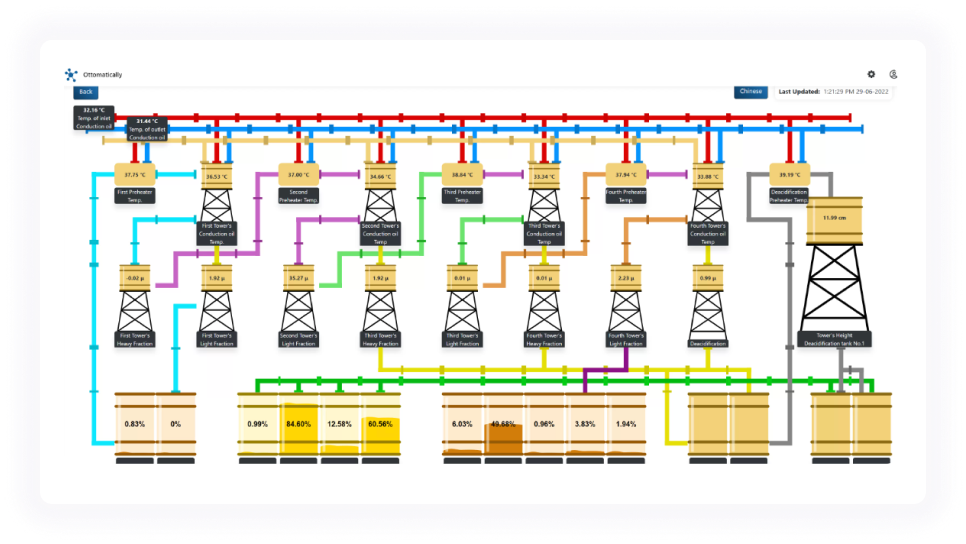

Digital Twin

Our Digital Twin solution creates a real-time virtual replica of a physical object, system, or process by integrating IoT sensors and data analytics. These sensors continuously collect data from the physical entity, which is then processed to update the digital twin. This virtual model mirrors the real-world object, allowing for real-time monitoring, simulation, and predictive analysis. Businesses can use these insights to optimize operations, predict maintenance needs, and improve decision-making, leading to increased efficiency, reduced costs, and enhanced performance across various industries like manufacturing, smart buildings, and asset management.